Welcome to RCS !

Solution

From the design of molds, to the production and assembly, to the testing and mass production of precision plastic products, as well as the full chain post-processing including UV printing, silkscreen printing, pad printing, automatic assembly, packaging, boxing, etc., RCS has been committed to providing customers with vertically integrated one-stop solutions and service support, starting from customer needs, further assisting customers in cost reduction and efficiency improvement.

-

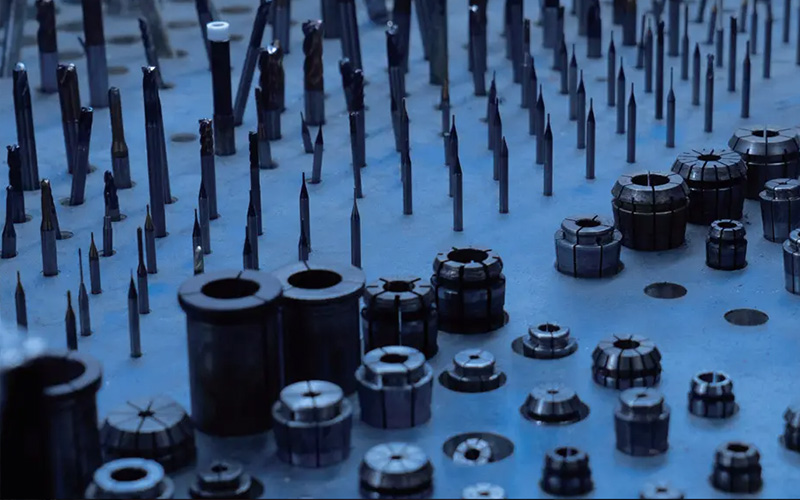

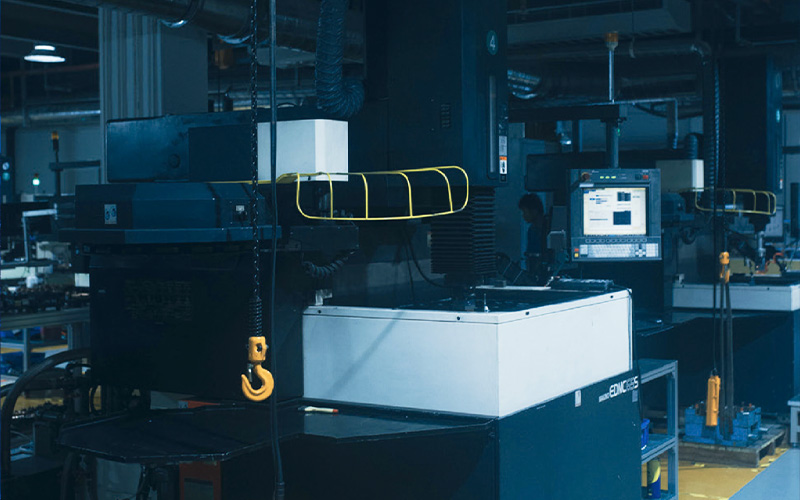

Precision Molds

Precision Molds

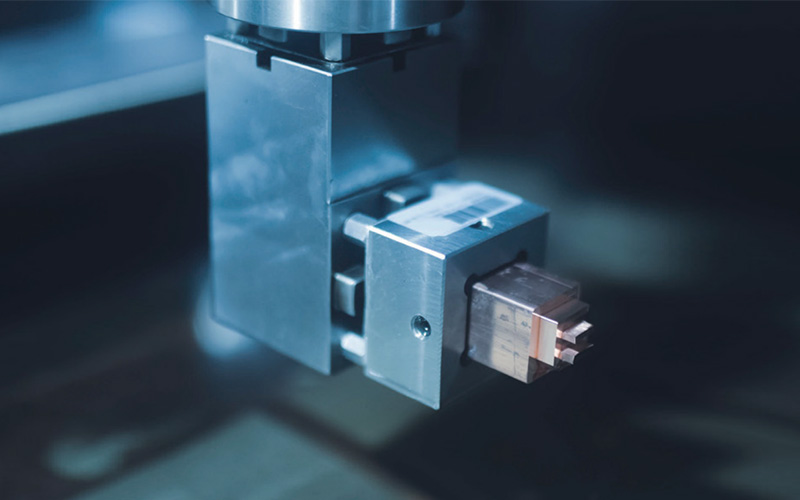

Precision injection molds can ensure the quality of plastic parts and greatly reduce the production cost of molds during the production process. Injection molds mainly utilize their specific cavity shapes to replicate and process molded products through the injection mechanism of plastics. Unlike traditional mold production, precision injection molds have the characteristics of high precision, high product quality, stable quality, large-scale production, and high-speed production. Throughout the production process of precision injection molds, there is a promising development prospect.

-

0° Draft Angle

0° Draft Angle

Plastic parts are produced by injection molding into molds, and after molding, they need to be pulled out. For the convenience of demolding, the ejection surface of injection molded parts is designed with a certain draft angle. Therefore, the smaller the draft angle, the higher the precision requirement of the product. As the name suggests, 0° draft angle, as the demolding angle of plastic parts is 0, shows the high precision and difficulty.

-

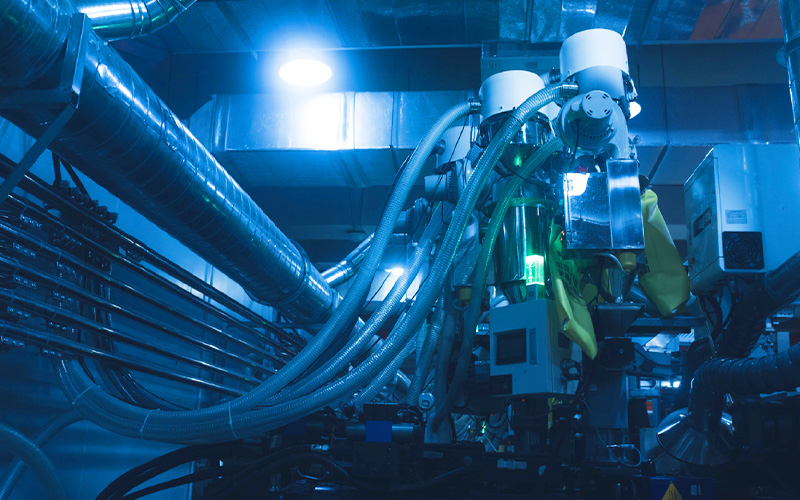

High-temperature

High-temperature

Injection molding refers to the process of heating the plastic material to reach a molten state, and then applying high pressure to the melted it to shoot it out and fill the mold cavity before cooling and forming. High temperature injection molding refers to the melting temperature of some high-temperature special plastic materials reaching 300 ° C or even higher, which requires relatively high performance of injection molding machines and auxiliary equipment. At the same time, it also tests the ability of technicians to control mold temperature and injection parameters. PEEK and PPSU, two types of special engineering materials, are commonly used high-temperature special adhesives in RCS production. Plastic parts made by injection molding them are mostly used in industries such as aerospace, automotive, medical, and electronic appliances.

-

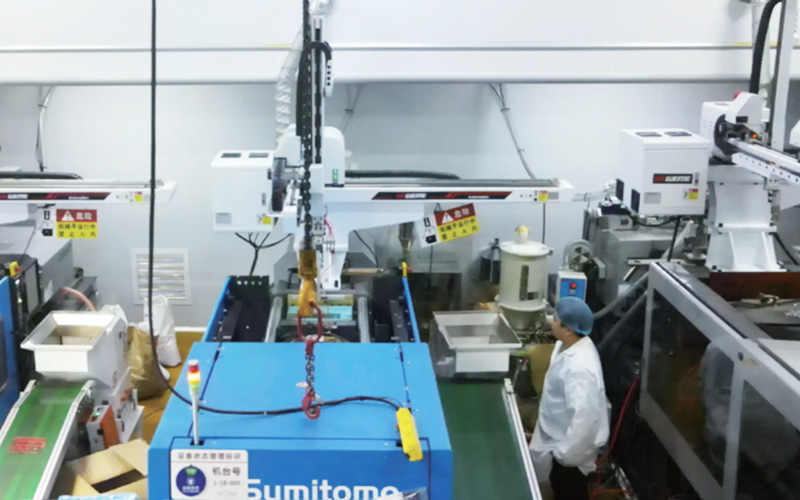

Clean Workshop

Clean Workshop

The injection molding parts in the medical equipment and precision electronics industries have certain requirements for cleanliness. RCS is equipped with a 100,000 level clean injection molding workshop that can accommodate 10 injection molding machines, mainly equipped with new Sumitomo injection molding machines from Japan, ensuring injection molding accuracy. The characteristics of a 100,000 level clean workshop are extremely high cleanliness, constant temperature and humidity, anti-static and dustproof, and equipped with an efficient air filtration system. At the same time, strict sealing measures are also adopted to prevent external pollutants from entering the clean area, effectively controlling the number of particles and microorganisms, and reducing the risk of product contamination. Injection molding production in a clean environment can better ensure the quality and stability of medical device parts and medical appliance products.

-

Double Shot

Double Shot

Dual color injection molding refers to the process of injecting two different materials into the same set of molds, in order to achieve the molding of parts formed by two different materials. Some of the two materials are of different colors, while others are of different softness and hardness. They can be used to make various mixed color patterned products, as well as products with clear color separation. Thereby improving the aesthetics and assembly performance of the product. The RCS injection molding workshop is equipped with several 250T dual color injection molding machines.

-

Multi Injection Molding

Multi Injection Molding

When developing a mold plan, RCS will recommend the most cost-effective cavity of mold designs based on the product's demand and geometric characteristics. Normally, the more cavities in the mold, the higher the production efficiency. However, since the first mock examination has multiple products arranged at the same time, in order to maintain a stable tolerance for the products produced at each point in batch production, strict control of injection molding parameters is required. RCS uses the MES system for injection molding production management, and at the same time, an efficient quality control team is equipped to ensure the efficient and high-quality production of multi cavities mold injection.

-

UV Printers

UV Printers

The RCS post processing department is equipped with up to 60 UV printers, with a monthly production capacity of 3 million parts. Compared to traditional printing, UV printing has fast speed and high accuracy, which can greatly improve production efficiency and quality; Can achieve three-dimensional design, making the product logo and style more diverse, and the touch better; Using UV ink is more environmentally friendly and energy-saving compared to traditional ink, while also reducing waste and pollution.

-

Automatic Assembly

Automatic Assembly

Automated assembly lines can be customized according to different needs. Automated assembly of robotic arms can significantly reduce labor and time costs, meet the needs of customers for large-scale procurement, and provide competitive cost performance for customers.

-

Automatic Packaging

Automatic Packaging

RCS can customize packaging from single product packaging to multi part combination packaging. Automated packaging lines can be customized according to different needs.