COMPANY INTRODUCTION

Dongguan Rongchangsheng Aerospace Technology Co., Ltd. (RCS) is a professional supplier of mold manufacturing and injection molding located in Dongguan, Guangdong. In over 2 decades of development in aviation, automotive, medical, precision toys, consumer electronics industries, RCS provided clients with high-quality products and services.

With more than 20 years of high temperature molding experience, RCS is now a leading domestic supplier of ultimate one-stop solution from mold design and manufacturing to plastic product mass production, printing, and packaging.

0

Establishment of The Company

0

+Number of Employees

0

Thousand ClassClean Injection Molding Workshop

0

MillionMonthly Production Can Reach 300 Million Parts

Company History

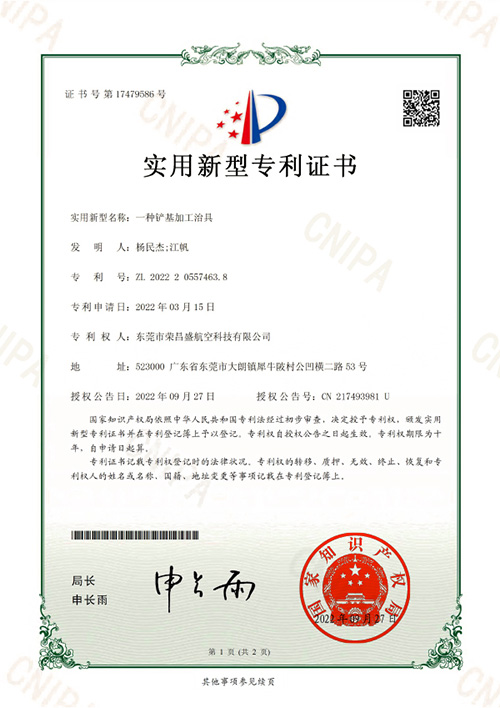

Honor and Certificates

MAJOR EQUIPMENT

| Equipment | Brand | Model | Processing Range | Machining Precision (mm) | Amount | Remark | |

|---|---|---|---|---|---|---|---|

| CNC Machining Center | MAKINO | V33i | 650X450X350 | 0.003 | 3 | 14 | |

| MAKINO | V33I GRAPHITE | 650X450X350 | 0.003 | 4 | Graphite Machine | ||

| JINGDIAO | JDGR300H | 510X390X300 | 0.003 | 1 | Five Axis Machine | ||

| MAKINO | F5 | 750X500X350 | 0.005 | 1 | |||

| MAKINO | F3 | 650X450X350 | 0.005 | 1 | |||

| GF | HSM500 | 550X450X350 | 0.005 | 2 | |||

| CHINGHUNG | HM6050C | 600X500X250 | 0.005 | 1 | |||

| FANUC | D14M1B | 400X300X250 | 0.01 | 1 | Copper Machine | ||

| EDM CNC Spark Machine | MAKINO | EDNC65 | 650X450X350 | 0.008 | 1 | 7 | |

| MAKINO | EDNC65S | 650X450X350 | 0.008 | 2 | C-axis, ATC | ||

| MAKINO | EDNC43 | 400X300X250 | 0.01 | 3 | |||

| MAKINO | EDGE2S | 300X250X250 | 0.005 | 1 | |||

| Wire Cut | SEIBU | M50B | 500X350X310 | 0.003 | 2 | 6 | |

| YINGJIANG | LX530 | 500X350X300 | 0.01 | 2 | |||

| YINGJIANG | LX640 | 600X400X300 | 0.01 | 2 | |||

| CNC Punching Machine | GF | DRILL 20 | 300X200X300 | 0.008 | 1 | 2 | |

| JINGBEN | HD-450 ATC CNC | 450X350X350 | 0.008 | 1 | |||

| Drilling Machine | HEXAGON | GLOBAL S 07.10.07 | 1000X700X700 | 0.001 | 2 | 6 | |

| HEXAGON | GLOBAL PLUS 08.06.08 | 800X600X800 | 0.001 | 3 | |||

| SEREIN | CROMA 8126 | 1200X800X600 | 0.002 | 1 | |||

| Projector | DLJM | DL4030-DCC | 400X300X200 | 0.005 | 1 | 8 | |

| TZTEK | VMU432 | 400X300X200 | 0.003 | 2 | |||

| Injection Machine | SUMITOMO | SE100DU | 100T(Moter) | / | 5 | 215 | |

| SUMITOMO | SE180DU | 180T(Moter) | / | 2 | |||

| SUMITOMO | SE180EV | 180T(Moter) | / | 1 | |||

| SUMITOMO | SE180DUZ | 180T(Moter) | / | 3 | |||

| SUMITOMO | SE130DU | 130T(Moter) | / | 1 | |||

| SUMITOMO | SE100EV-A | 100T(Moter) | / | 5 | 2 | ||

| SUMITOMO | SE220EV | 220T(Moter) | / | 2 | |||

| HAITIAN | MA2500 | 250T | / | 6 | |||

| HAITIAN | MA3800 | 380T | / | 1 | |||

| HAITIAN | MA7000 | 600T | / | 1 | |||

| HAITIAN | MA1200IlI | 120T | / | 138 | |||

| HAITIAN | ZE1200III | 120T(Moter) | / | 2 | |||

| HAITIAN | 1A2500 | 250T(2K) | / | 48 | |||

| UV PRINTING | SHENGHUANGKE | SHK-1612 | 1600X1200 | / | 10 | 60 | |

| HENGCHENGWEIYE | HC-1612 | 1600X1200 | / | 37 | |||

| ZHONGCAI | KGT-1216 | 1600X1200 | / | 13 | |||

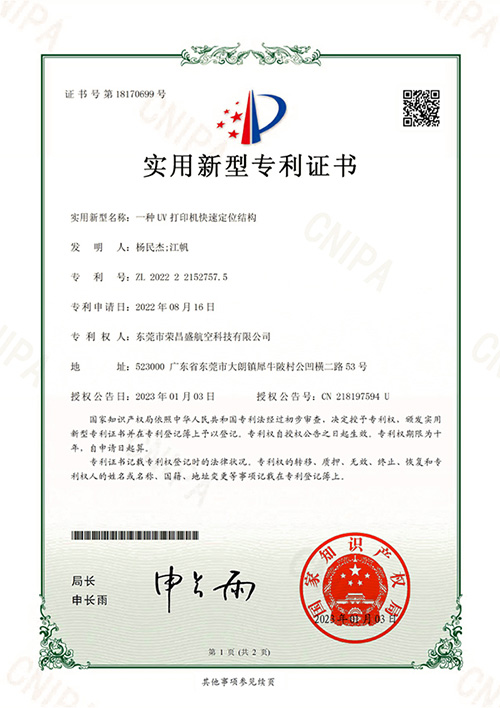

R&D Team

A professional independent R&D team with over 20 years of experience in high-temperature precision mold processing and injection molding, has successfully developed and obtained multiple independent research and development patents.

Join Us

-

Quality Control Officer6k-8kUnlimitedQuality inspector/Tester

Job Responsibilities

1. Responsible for incoming material inspection and status identification, and reporting abnormal incoming materials;

2. Monitoring and quality reconfirmation during incoming material selection, heavy industry process;

3. Responsible for the return of samples and related materials after inspection;

4.Confirmation of incoming material defects during the manufacturing process;

5. Fill out the incoming material inspection report;

6.Feedback on problem points in incoming material inspection work;

7. Assist in emergency material rework work;

8. Maintenance of 5S in the inspection area。

Job Requirements

Age requirement: unlimited

Language requirements: unlimited